By Jeff Pederson – Pedal Down Promotions

Unfavorable operating conditions can be highly problematic within the inner workings of an electric motor assembly, shortening the staying power of a three-phase stator winding system.

Whether electrical, mechanical or environmental in nature, Acme Armature Works Inc. owner Chad Bahrs says identifying potentially detrimental operating conditions plays a key role when diagnosing specific reasons for three-phase stator winding failures.

“When a customer brings in an electric motor with a three-phase stator winding failure, I think it is very important to tell the customer why it failed,” Bahrs said. “There are a lot of different reasons for these types of failures, so we always dig deep to find out what happened. Knowing the reason why a failure occurred can teach us a lot and help our customers in taking preventative measures to avoid having that type of failure happen again.”

Common winding failures in three-phase stators can be wide ranging in nature as outlined by the Electrical  Apparatus Service Association (EASA).

Apparatus Service Association (EASA).

Single-phased winding failures are typically the result of an connection issue in one phase of the power supply to the motor caused by a blown fuse, open contactor, broken power line or bad connection.

Thermal deterioration of insulation in one phase of the stator winding can result from unequal voltage between phases caused by unbalanced loads on the power source, poor connection at the motor terminal or high resistance contact, such as a weak spring.

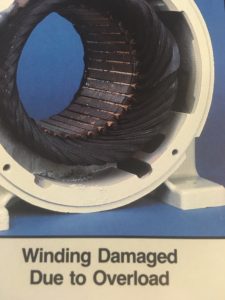

Thermal deterioration of the insulation in all phases of the stator windin g is typically caused by load demands exceeding the rating of the motor. In addition, under-voltage and over-voltage, which exceed NEMA standards, will also produce the same type of insulation deterioration.

g is typically caused by load demands exceeding the rating of the motor. In addition, under-voltage and over-voltage, which exceed NEMA standards, will also produce the same type of insulation deterioration.

Severe thermal deterioration of the insulation in all phases of the motor normally is caused by very high currents in the stator winding due to a locked rotor condition. This can also occur as the result of excessive starts or reversals.

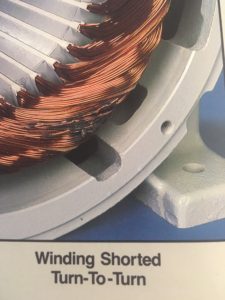

The presence of contaminants, abrasion, vibration or a voltage surge can produce insulation failures.

The presence of contaminants, abrasion, vibration or a voltage surge can produce insulation failures.

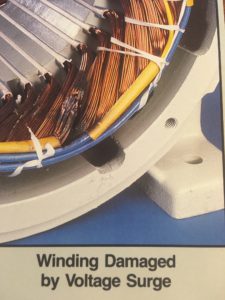

Voltage surges, which are often the result of switching power circuits, lighting strikes, capacitor discharges and solid-state power devices, can produce insulation failures.

“Any time you have unbalanced voltage in a three-phase stator winding system, damage can occur,” Bahrs said. “When we repair these types of failures, we always stress the importance of learning why the failure occurred. It is always a good practice to keep our customers informed and give them tips to avoid running into a similar situation in the future. Communication with our customers is key and we always place a high value on that.”

For more information about how Acme Armature Works Inc. can help to diagnose the causes of failures in three-phase stator windings in your electric motor assembly, email [email protected], call the 24-hour service line at 920-452-3389 or visit www.acmearmature.com.

By attending the course and passing a written test, Bahrs was able to obtain an additional two-year extended warranty on all LSIS variable frequency drives sold at Acme Armature Works.

By attending the course and passing a written test, Bahrs was able to obtain an additional two-year extended warranty on all LSIS variable frequency drives sold at Acme Armature Works.